Battery Electrolyte & HV Battery Leak Tester – Specifically for Aftersales and Workshops

For HV-EV Battery Aftersales Service, Repair Workshops, and Battery Packs in Production

Workshop and Aftersales Application

Application and Function – Electrolyte Leak Detection

The RC01-E Battery Electrolyte Leak Tester is connected to the fully sealed high-voltage battery. With its integrated vacuum pump, the device extracts air from the battery housing and analyzes it for the concentration of electrolyte vapors (in ppm).

The permissible threshold can be configured according to OEM specifications.

The result is clearly displayed as PASS or FAIL:

- PASS – No electrolyte vapors detected

The battery can be safely opened and repaired under normal workshop conditions. - FAIL – Electrolyte vapors detected

The battery may only be opened in a controlled safety environment, as escaping electrolyte vapors pose health risks and may indicate internal cell or module damage.

The test duration is usually 10–30 seconds, depending on the internal volume of the battery.

Application for Quality Assurance in Battery Production and Repair

Application in Battery Production and Pack Assembly

The RC01-E is also designed for quality assurance in battery manufacturing.

During the laser welding of battery cells and contact plates, invisible micro-cracks can occur in the cell housing. If a weld overheats or burns through, electrolyte can escape – leading to the following problems:

- Health risks for production personnel

- Reduced cell performance or complete cell failure

- Increased rework and scrap rate

To detect such defects early, the battery module or battery pack is placed in an airtight test chamber (standard volume approx. 10 L) and connected to the RC01-E.

The device creates a vacuum and analyzes the extracted air for traces of electrolyte vapors – thus, leaks can be detected quickly and reliably before the product reaches the next manufacturing step or is delivered.

Larger chambers or customized process parameters can be configured upon request.

Quality Assurance after Repair or Service

After completion of repair work, a post-check for electrolyte leaks can be performed with the RC01-E to validate the repair.

Electric Vehicle Battery Leak Test – Specifically for Aftersales and Workshops

In addition, the device features two pressure-based leak tests:

- Low-pressure leak test

- High-pressure leak test

All test results are automatically stored in an integrated database, enabling:

- Full traceability of all diagnostic and repair steps

- Quality documentation for customers

- Compliance with OEM and audit requirements

This ensures that every serviced battery meets the specified safety, reliability, and performance standards before being put back into operation.

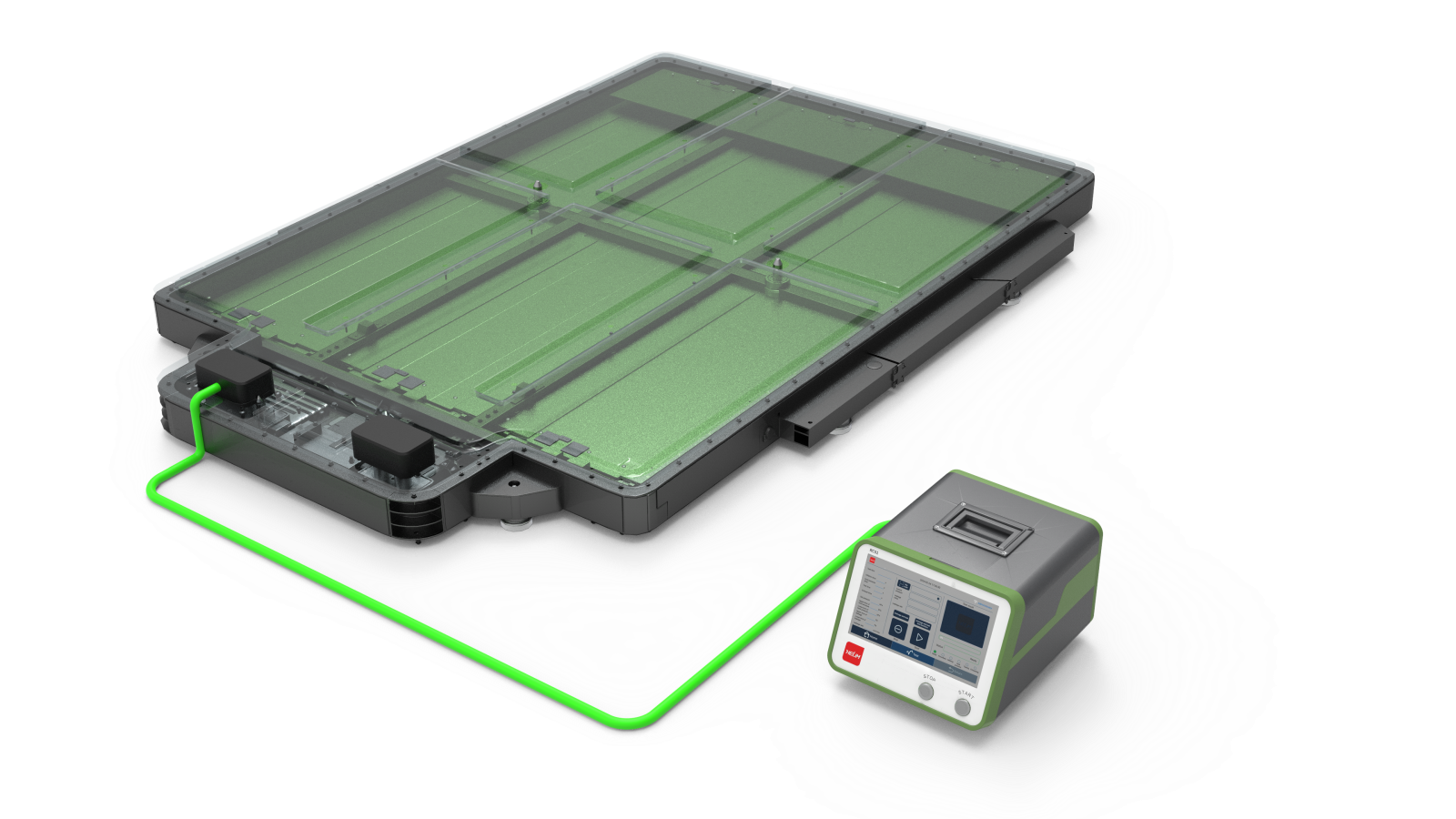

Low-pressure – Leak test of the battery housing after assembly

After reassembling a high-voltage battery, the housing must be checked for leaks. A low-pressure test is carried out using a leak tester. The targeted introduction of air is used to check whether the housing is completely sealed. This ensures that no moisture or harmful gases penetrate the battery. A reliable leak tester is important to ensure the long-term safety and function of the battery.

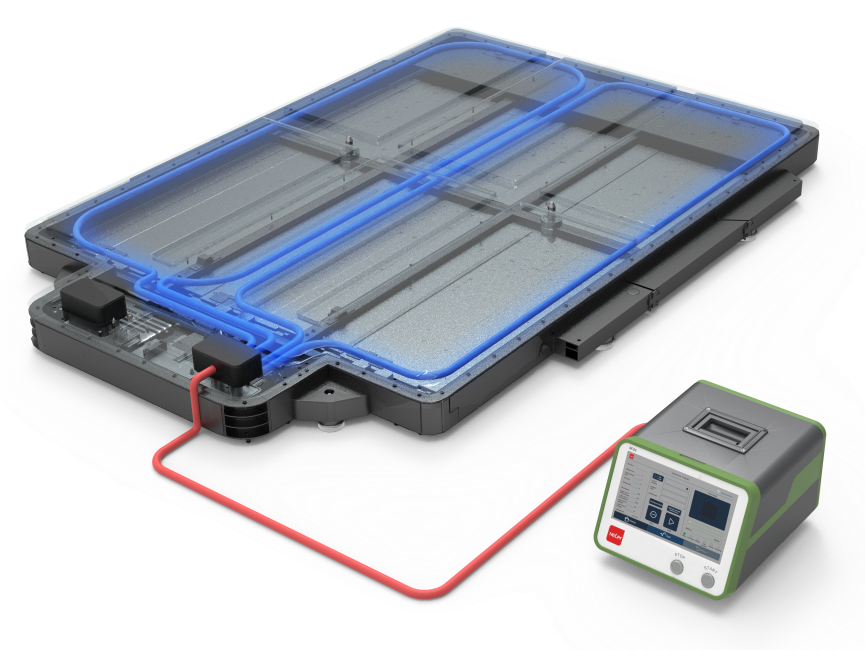

High-pressure – Leak test of the battery cooling circuit after repair

After repairing a high-voltage battery, the cooling circuit must be checked for leaks. To do this, a high-pressure test with air is carried out using a leak tester. This allows even the smallest leaks to be reliably detected and repaired. It is particularly important that no cooling medium escapes from the system, as otherwise cooling water can get into the battery cells and cause damage. This test ensures that the cooling system is working properly and that the battery does not overheat. A leak tester helps to check the quality of the repair and protect the service life of the battery.

Developed for Aftersales Service & Industrial Manufacturing

| Application Area | Purpose | Benefits |

| HV-EV Battery Aftersales & Repair Workshops | Safe assessment of sealed batteries before opening; verification after repair | Increased safety for technicians, minimized risk, validated repair quality |

| Battery Production & Pack Assembly | Inline or End-of-Line Leak and Electrolyte Detection | Less rework, higher production yield, reliable quality control |

The RC01-E is thus a dual-function solution:

✔ Battery electrolyte tester for EV repair and workshop safety

✔ HV-EV battery leak tester for production and assembly quality assurance

High-pressure test for the battery cooling system

Low-pressure testing of the battery housing

10.1″ touchscreen for intuitive

operation

Android 4.4.2 – easy operation

Storage capacity for up to 10,000 test results, exportable via USB.

Up to 1,000 customizable test programs.

Integration of a barcode scanner for efficient workflows

Test history

Optimized for use in the workshop

Practical carrying handle

External pressure display

USB port for data and barcode scanner

RS232 Port

Compressed air Port

Integrated air filtration and oil separator

Test Port

Robust aluminum housing for long-term use

Automatic pressure regulation

Power connection

Air Leak and Electrolyte Testing for Electric Vehicle Batteries – Reliable Leak Testing after Maintenance, Repair, and Production

Modern electric vehicles (EVs) rely on powerful high-voltage batteries (HV batteries). To ensure the safety, performance, and lifespan of these energy storage units, precise air leak and electrolyte testing after maintenance, repair, or in battery production is indispensable.

Our HV Battery Leak and Electrolyte Tester was specially developed for workshops, aftersales services, and production lines. The device enables fast, safe, and documented inspection of battery modules and packs.

Why Air Leak and Electrolyte Testing is so Important

High-voltage batteries are sensitive to moisture, pressure differences, and chemical changes.

Even the smallest leaks can lead to corrosion, performance loss, or safety-critical defects.

Furthermore, leaked electrolyte can pose significant health and fire risks and indicate internal cell damage.

Reliable testing ensures that:

-

the safety of technicians and workshop personnel is ensured

-

Defects are detected early

-

the battery meets OEM and quality requirements

-

the lifespan and performance of the battery are maintained

Features and Benefits of the HV Battery Leak and Electrolyte Tester

-

Fast tests: test duration of 10–30 seconds depending on battery volume

-

High sensitivity: detects even the smallest leaks and electrolyte vapors

-

Two test modes for leak testing:

-

Low-pressure test for housing tightness

-

High-pressure test for cooling systems and cooling plates

-

-

Electrolyte detection: measures electrolyte vapors in ppm for safe assessment before opening

-

Easy handling: intuitive operation for workshop and production teams

-

Documentation: all test results are automatically saved, for quality records and audit requirements

Areas of Application

-

Workshops & Aftersales

After every maintenance or repair of HV batteries, testing ensures complete tightness and early detection of potential defects. -

Battery Production & Pack Assembly

During manufacturing, micro-cracks or welding defects can occur. With air leak and electrolyte testing, leaks are detected before delivery, reducing rework and production loss. -

Research & Quality Assurance

For laboratories and test centers, the tester provides precise measurements that meet safety standards and OEM requirements.

Conclusion

The combined air leak and electrolyte testing is a crucial step for the safety, quality, and longevity of electric vehicle batteries.

Whether in the workshop, aftersales service, or production – with our HV Battery Leak and Electrolyte Tester, leaks are reliably detected and potential damage is prevented.

Contact us to receive further information or discuss a customized offer for your company.